Streamlining Factory Labelling with In-Line Printing Solutions

In today's fast-paced manufacturing environments, efficiency and accuracy are paramount. Conventionally, factories relied on centralised printing areas for label production, followed by manual sorting and distribution to various workstations. While this method has been the standard, it comes with several drawbacks.

1. High Labour Costs:

The need for manual sorting and distribution increases labour costs.

2. Human Error:

Manual sorting is prone to mistakes, leading to mislabelled products.

3. Inconsistent Serial Numbers:

Pre-printed labels often result in inconsistent serial numbering, complicating inventory and quality control.

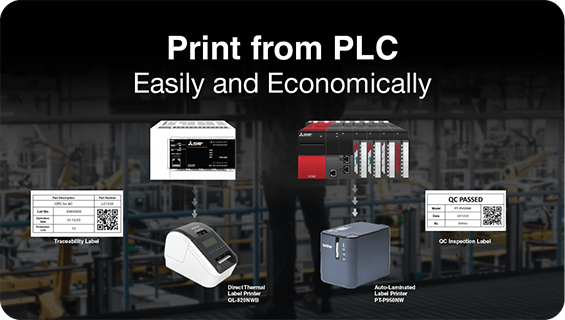

To address these challenges, Brother offers a cutting-edge in-line printing solution that integrates seamlessly with factory automation systems, particularly those utilising PLCs (Programmable Logic Controllers).

The Benefits of Brother's In-Line Printing Solution

1. Reduced Labour Costs

By integrating label printing directly into the production line, the need for manual sorting and distribution is eliminated. Labels are printed and applied on-site, reducing the labour required and allowing staff to focus on more critical tasks.

2. Enhanced Accuracy

Automating the labelling process minimises the risk of human error. Labels are printed precisely when and where they are required, ensuring that each product is correctly identified and reducing the chances of mislabelling.

3. Consistent Serial Numbers

In-line printing allows for real-time printing of serial numbers, ensuring consistency and accuracy. This feature is particularly beneficial for industries that require strict traceability and quality control, such as pharmaceuticals and electronics.

Seamless Integration with PLC Systems

Brother's in-line printing solutions are designed to integrate effortlessly with PLC systems, such as those from Mitsubishi Electric. This integration enables real-time data exchange between the PLC and the label printer, ensuring that labels are printed with the correct information as products move through the production line.

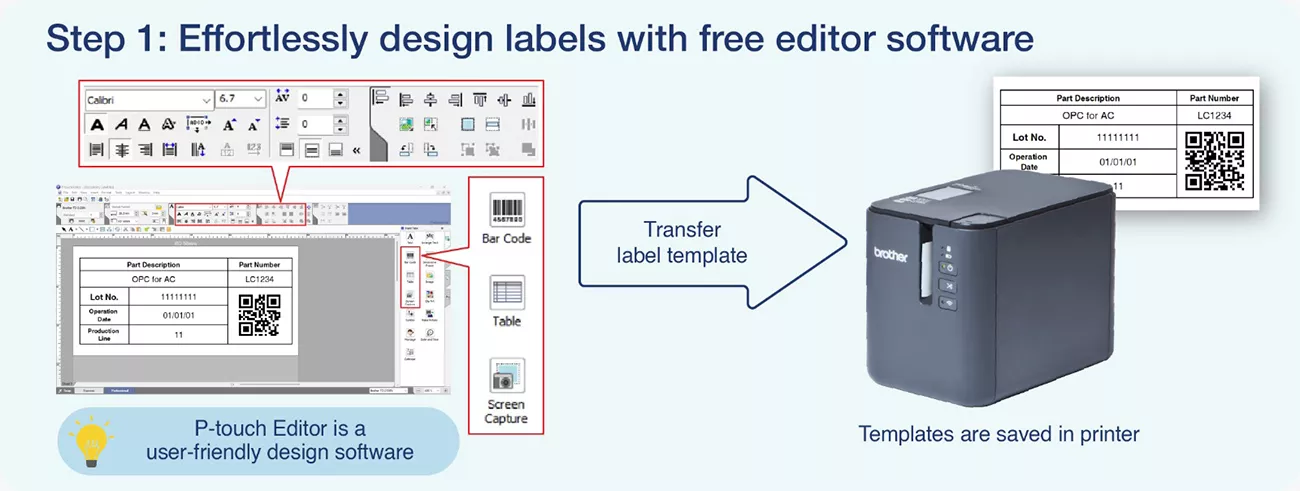

User-Friendly Label Design Software

Brother's label design software is intuitive and easy to use, allowing you to quickly design and customise labels to meet their specific needs. The software supports a wide range of label formats and data inputs, making it versatile enough for various applications.

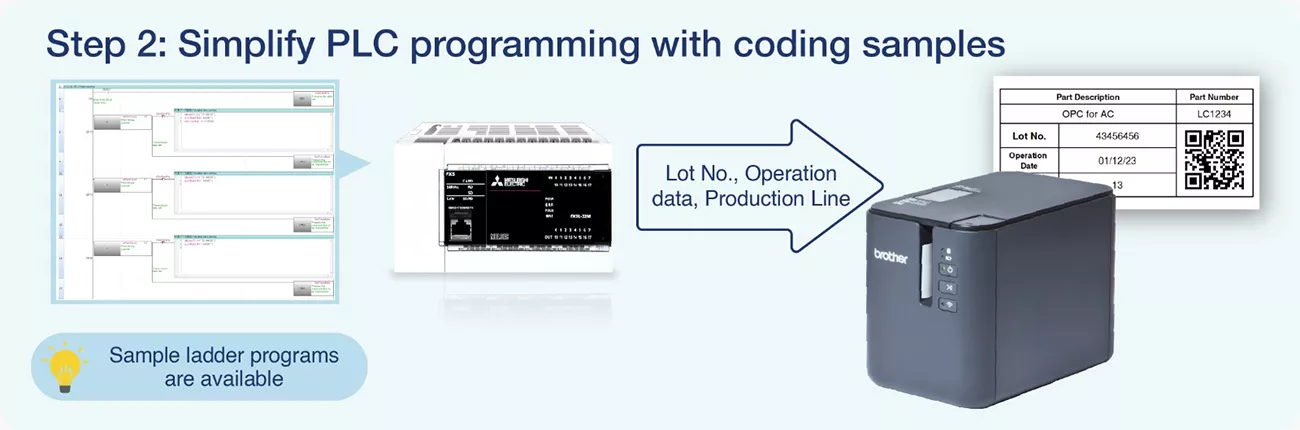

Sample Programs and Manuals

To facilitate easy implementation, Brother provides sample programs and comprehensive manuals for Mitsubishi Electric PLCs. These resources guide users through the setup process, making it simple to integrate the in-line printing solution into existing systems.

Conclusion

Brother's in-line printing solution represents a significant advancement for factories seeking to enhance efficiency and accuracy in their labelling processes. By reducing labour costs, minimising errors and ensuring consistent serial numbers, this solution addresses the common challenges associated with conventional labelling methods. With easy integration into PLC systems and user-friendly software, implementing Brother's in-line printing technology is a straightforward and impactful upgrade for any factory.